Precautions for the installation of pneumatic control valves

- Jun 4, 2024

- 2 min read

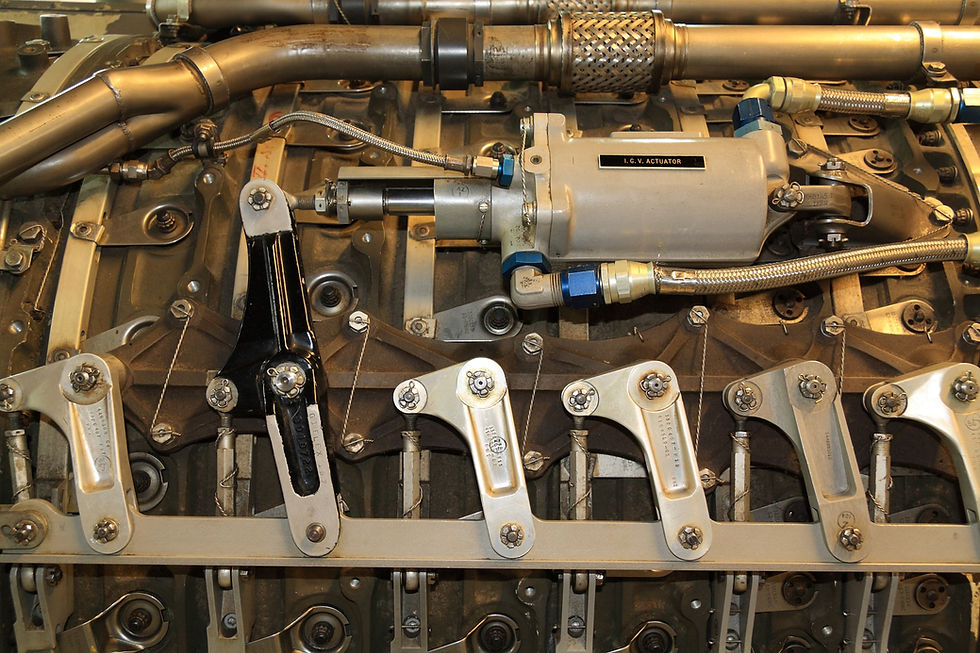

Pneumatic adjustment is to use compressed gas as the power source, cylinder as the actuator, and with the help of valve positioner, converter, solenoid valve, position retention valve, gas storage tank, gas filter and other accessories to drive the valve, realize the switching or proportional adjustment, and receive the control signal of the industrial automation control system to complete the adjustment of the pipeline medium: flow, pressure, temperature, liquid level and other process parameters.

Installation Precautions:

1. During the installation process, the installation instructions and precautions of the pneumatic control valve should always be observed;

2. The working environment temperature of the control valve should be (-30~+60) relative humidity is not more than 95% 95%, and the relative humidity is not more than 95%;

3. There should be a straight pipe section at the front and rear positions of the control valve, and the length should not be less than 10 times the pipe diameter (10D), so as to avoid the straight pipe section of the valve being too short and affecting the flow characteristics.

4. Read the instruction manual before installing the valve. The instruction manual describes the product and the safety precautions and precautions that should be taken before and during installation:

5. Confirm that the pipe is clean: Foreign objects in the pipe may damage the sealing surface of the valve or even hinder the movement of the valve core, ball or butterfly plate, causing the wide door to not close properly. In order to reduce the possibility of a hazardous situation, all pipes need to be cleaned before installing the valve. Confirm that the pipe has been cleaned of dirt, metal chips, weld slag and other foreign objects. Also, inspect the pipe flange to make sure there is a smooth gasket surface. If the valve has a threaded end, apply a high-grade pipe sealant to the pipe male thread. Do not apply sealant to the female thread as excess sealant will be squeezed into the wide body. Excess sealant can cause jamming of the spool or accumulation of dirt, which in turn can cause the valve to not close properly:

6. We carefully inspect the control valve: before installation, inspect and remove all caps on the surface of transport stops, protective plugs or gaskets, and inspect the inside of the valve body to ensure that there are no foreign objects:

7. The control valve should be installed on the horizontal pipeline,

Comments